As the rise of smart machines and cyber-physical systems brings us into the fourth Industrial Revolution (or Industry 4.0), the tasks being performed by robots on the line are becoming progressively more complex. Using vision guided robotics (VGR) capabilities, robotic applications are fitted with one or more cameras that provide feedback signals to more accurately move a robot to a variable target position.

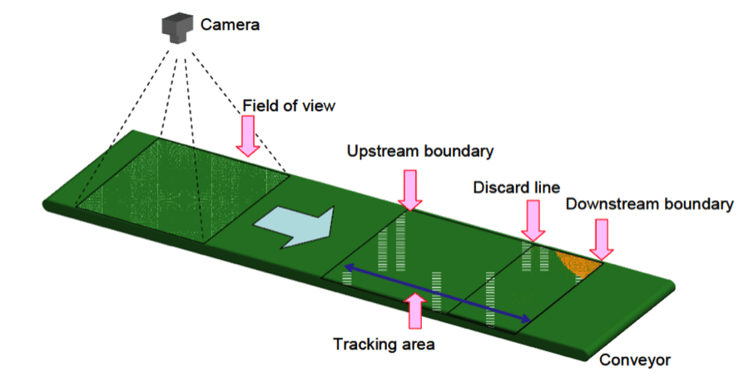

The diagram below shows a typical production line VGR system setup.

When developing a VGR application, precision is key. Therefore, it is essential to consider all of your variables from the very beginning to ensure you create the most efficient and effective system. Some of the key items to think about when getting started with a VGR system include the following:

- Lighting—The natural and artificial lighting in the room where the machine will be located needs to be given careful consideration because any change in lighting can skew the robot’s vision.

- Camera resolution—Calculating resolution requires knowing the size of the field of view and knowing the smallest feature that needs to be detected.

- Proper calibration—Typically, this bridge between the vision system and robot is a shared coordinate system where the camera identifies a target and converts the position of that target from camera coordinates (pixels) to real-world coordinates for the robot. Because this communication needs to be performed with micro-millimeter accuracy, proper calibration of the entire system is crucial.

- Expertise—Because of the complexities involved in developing VGR applications, you will likely see the best results by working with an expert system integrator to design, develop, and deploy your VGR application. When selecting a system integrator for your VGR application, it is important to ensure the integrator possesses a high level of expertise with vision, robotic, and automation applications.

By thinking about these items from the very beginning, you are more likely to get your VGR application functioning correctly the first time, saving you a lot of headaches and debugging later.

As vision and robotic control technology continue to advance, VGR applications are performing increasingly complex tasks and becoming even more sophisticated, delivering measurable ROI for manufactures, typically in less than 18 months. Thanks to more sophisticated industrial automation of manufacturing with VGR, the factory of the future will continue to become increasingly efficient, more cost-effective to run, and a safer environment for employees.

To learn more about the benefits a VGR systems can bring to your production line, download the full white paper.

PrimeTest Automation will consistently provide products and services utilizing the latest technologies that meet or exceed the requirements and expectations of our customers. We will actively pursue improvements in quality through programs that benefit the growth of each employee and systems that promote efficiency throughout our organization.

PrimeTest Automation will consistently provide products and services utilizing the latest technologies that meet or exceed the requirements and expectations of our customers. We will actively pursue improvements in quality through programs that benefit the growth of each employee and systems that promote efficiency throughout our organization.