At PrimeTest Automation, we have more than 15 years of experience developing industrial automation solutions for a wide variety of clients. Perhaps the most important thing we’ve learned during this time is that when it comes to machine automation, there are no hard and fast rules. Instead, there are guidelines and best practices that should be followed.

As a result of our experience, we’ve compiled the following “10 Commandments for Automation Machine Engineering:”

- Do Not Rely on Gravity—Never assume a part guided by gravity will land where you intended it to go.

- Start With a Solid Foundation—Use steel instead of aluminum for a machine base.

- Always Verify Part Presence—Don’t assume anything, verify everything.

- Use a Through-Beam Sensor Whenever Possible— This is the most reliable method for indicating that a part is present.

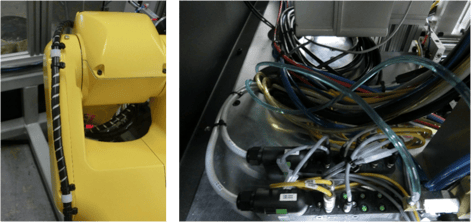

- Cable Management Should Not Be an Afterthought—Design cable and enclosures into the machine.

The machine on the left takes advantage of cable management best practices by using spiral wrap to properly protect the cabling, while the example on the right shows many exposed cables and wires that are likely to get damaged over time.

- Nothing Gets Fixed in the Truck—A thorough machine run off is the last opportunity to make modifications.

- Once You Orient a Part, Don’t Let it Go—Once a part is properly placed into your machine, don’t let it go.

- Don’t Try to Create a “Do All” Process or Machine— By using simple steps and processes, setup and troubleshooting becomes straightforward so if something breaks, it’s easier and quicker to repair.

- When in Doubt, Upsize—The cost associated with upsizing a part from the beginning is minimal compared to the cost of rebuilding a marginal process down the line.

- Just Because You Can Write Software for a Function, Doesn’t Mean You Should—Think about what is essential for the operator to know and keep the software straightforward.

At PrimeTest Automation, we may not have these commandments posted on the wall of our shop, but these best practices are agreed upon and engrained into every one of our engineers. We know that to keep our customer’s production systems consistently functioning, it is important to design and develop machines with minimal downtime and ultimate reliability. Thus, we focus on having proper foresight and use these commandments to focus on simplicity, verification, and risk mitigation to develop automated machinery that is built to last.

Download the 10 Commandments of Automation Machine Engineering whitepaper to learn more about these 10 guidelines and how they can help you ensure success in your industrial automated solutions.

PrimeTest Automation will consistently provide products and services utilizing the latest technologies that meet or exceed the requirements and expectations of our customers. We will actively pursue improvements in quality through programs that benefit the growth of each employee and systems that promote efficiency throughout our organization.

PrimeTest Automation will consistently provide products and services utilizing the latest technologies that meet or exceed the requirements and expectations of our customers. We will actively pursue improvements in quality through programs that benefit the growth of each employee and systems that promote efficiency throughout our organization.